Ultrasonic atomizer method for coating QCM odor/gas sensors

Quartz crystal microbalance (QCM) sensors coated with various sensing films have been useful for gas/vapor detection and analysis.

Stability and reproducibility of the QCM sensors is crucial for realisation of the Odor Sensing

and Odor Recording systems and depend strongly on quality of deposited sensing films.

To address those issues our group has been developing a method for coating the gas/odor sensing materials onto QCM sensors by means of an ultrasonic atomizer.

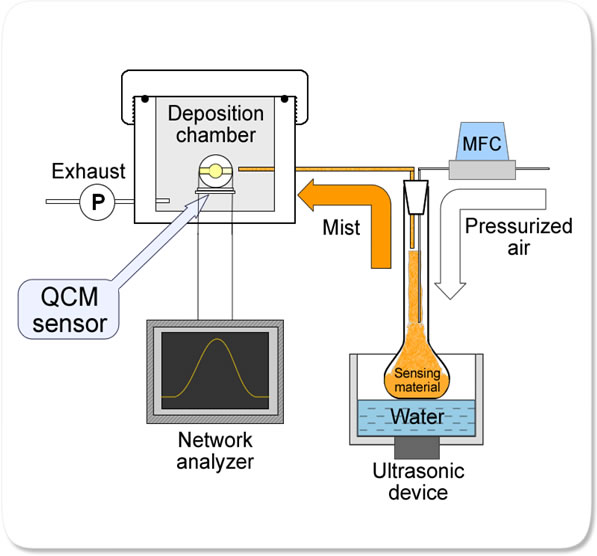

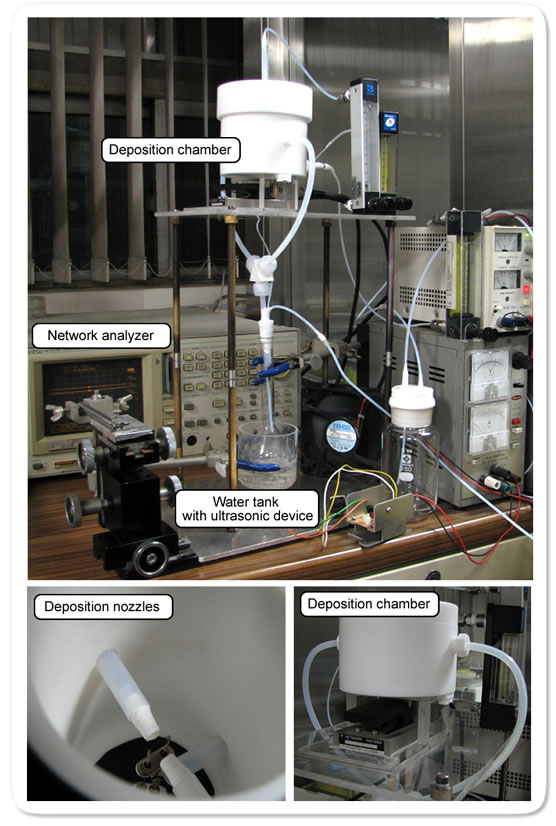

The method relies on atomization of the sensing material solution into fine particles and carrying them onto the QCM sensor surface. Pressurized dry air is used to elevate particles of the produced mist. Extracting pump creates subpressure in the system whcih allows for the mist to be carried to the deposition chamber. The deposition process is monitored online using network analyzer.

The method relies on atomization of the sensing material solution into fine particles and carrying them onto the QCM sensor surface. Pressurized dry air is used to elevate particles of the produced mist. Extracting pump creates subpressure in the system whcih allows for the mist to be carried to the deposition chamber. The deposition process is monitored online using network analyzer.

As the sensing materials are dissolved in chloroform, all the part being in contact with solutions or mist are made of PTFE.

The deposition chamber is carefully sealed to control environment of the QCM sensor during deposition process.

Deposition nozzles are positioned carefully to preserve proper distribution of coated particles on the sensor surface.

What is the advantage of using ultrasonic atomizer technique?

Very briefly - the advantage is quality and reproducibility of the fabricated sensors.

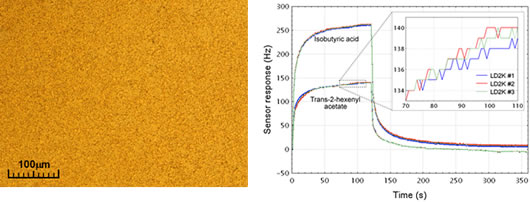

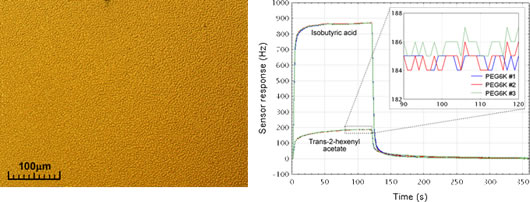

You can see below results of coating two different sensing materials - poly(ethylene glycol) and lipopolymer - microscope image of the sensor surface

and responses of sensors to different odorants.

The materials are distributed evenly over the surface, and improved control over the deposition results in great sensor-to-sensor response reproducibility.

Sensors coated with Poly(ethylene glycol) 6000

Sensors coated with Lipopolymer (tether: PEG 2000)